To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

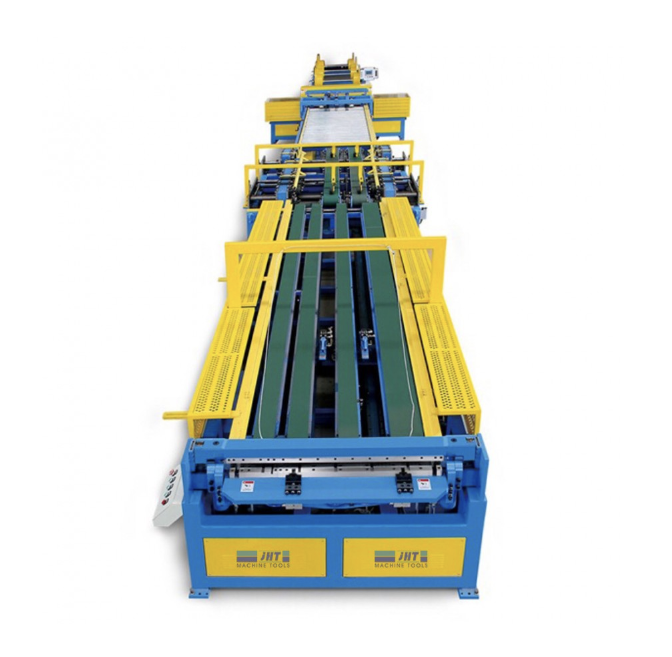

View more details here Square Auto Duct Line V

New $49,500.00

The linear structure of JHT Square Auto Duct Line V makes processing smoothly and occupies a small space.

2.All the rolling reels are made of bearing steel so that the lifetime prolongs by more than 5 times.

3.Under the material-saving mode of CNC system, waste is less than 20 mm per roll.

4.The locating system is very accurate with servo feeding mechanism, especially when processing square-shaped pipes.

5.It's equipped with 10 inch LCD touch screen and optional dual keyboard mode to keep operation stable.

6.JHT Square Auto Duct Line V requires at least one person to operate and each shift can output 600-2000㎡/day.With production memory functions, the production orders can be tracked and checked.

II. Main Functions

1.JHT Square Auto Duct Line V mainly used for processing TDF flange straight pipe and angle flange “C” bone flange, production capacity: 600-2000㎡/day.

2.Only need input size, production line could automatically uncoiling, leveling, bending grooving, notching, Pittsburgh lock, TDF flange forming, angle flange ‘C’bone flange forming, folding square.

3.Leveling roller isΦ70 solid roller, made by 45# hardening and tempering steel coated with hard chrome to ensure service life and leveling effect, and protect the metal sheet surface.

4.Grooving roller isΦ100 solid roller, made by 45# hardening and tempering steel coated with hard chrome to ensure service life and grooving effect and beauty-appearance.

5.Conjunction with hydraulic shearing machine whose blade made by 6CrWu2Sisteel, ensures the cutting accuracy ±0.5mm without turned edge and burr.

III. Standard Accessories

1.Two electric coil cradles, 4 material trays (5-7t each roll)

2. One rack

3. One host (line 2 host)

4. One mechanical arm clutching, locating and transferring platform

5. One displacement type locking machine

6. One duplex TDF flange forming machine

7. One duplex angle steel flange forming machine

8. One servo feeding platform

9. One hydraulic folding machine

10. One set of computer controlling system

Copyright 2026 © Machine Matcher.