To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

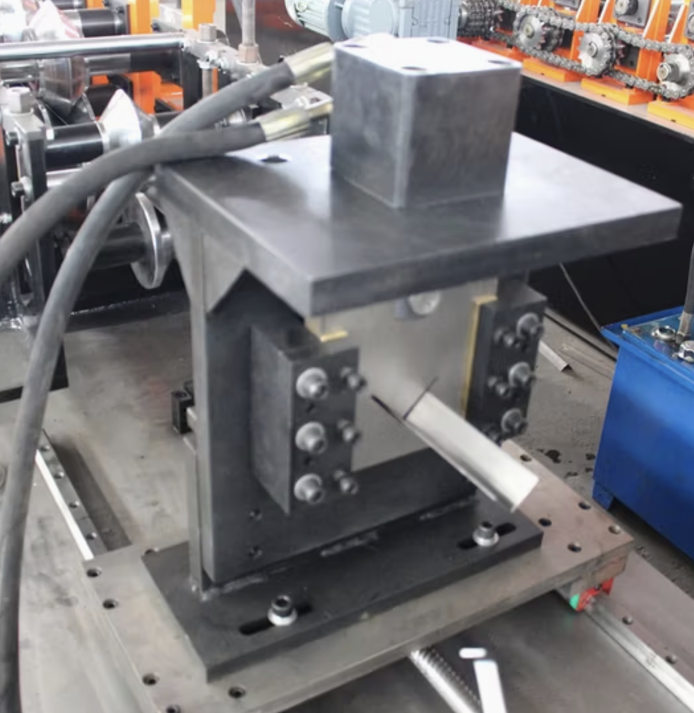

A Wall Angle Roll Forming Machine is a highly specialized equipment designed to produce wall angles used in suspended ceiling systems. These wall angles, also known as corner profiles, serve as support structures in ceiling installations. This machine automates the production process, ensuring precision, consistency, and efficiency, which are essential for large-scale manufacturing.

Wall angle profiles are typically made from galvanized steel, aluminum, or stainless steel and come in various sizes and thicknesses. The machine is equipped with advanced technology to produce high-quality angles that meet the requirements of modern construction and architectural projects in the USA.

Here are the typical specifications of a Wall Angle Roll Forming Machine:

Wall angle profiles produced by this machine are used in:

Q1: What materials can a Wall Angle Roll Forming Machine process?

A: This machine processes galvanized steel, aluminum, and stainless steel, with thicknesses ranging from 0.3 mm to 0.8 mm.

Q2: How does the machine handle different profile sizes?

A: The machine includes adjustable settings and interchangeable rollers, allowing it to produce various profile sizes.

Q3: Can the machine be customized for unique profiles?

A: Yes, the machine can be customized for specific profile dimensions, hole punching, and material requirements.

Q4: What is the production speed?

A: The machine operates at speeds of 30 to 50 meters per minute, depending on the material and profile complexity.

Q5: Does the machine meet US power standards?

A: Yes, the machine can be configured to meet US power standards, typically 480V/60Hz.

Q6: What maintenance is required?

A: Regular maintenance includes lubrication of moving parts, checking for wear on rollers and cutting blades, and ensuring the PLC system is functioning correctly.

Q7: Is training provided with the machine?

A: Many manufacturers and sellers offer training and installation support to ensure proper operation.

Copyright 2026 © Machine Matcher.