Posted on Thursday, January 15, 2026

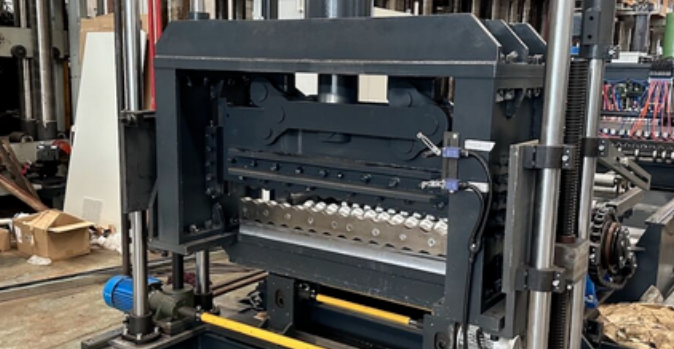

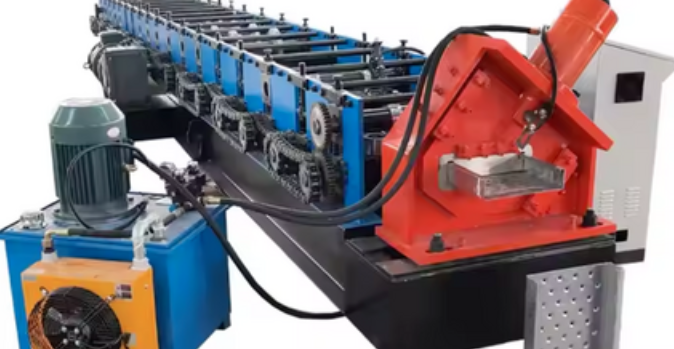

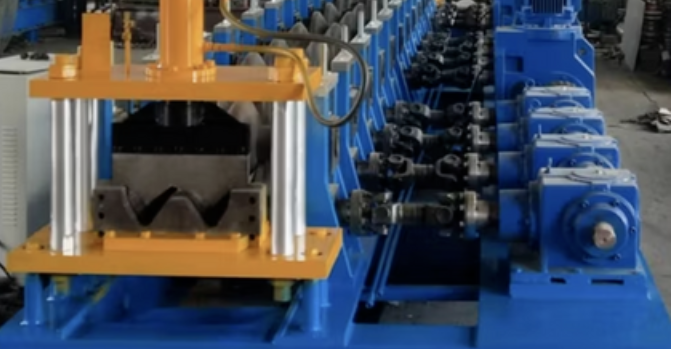

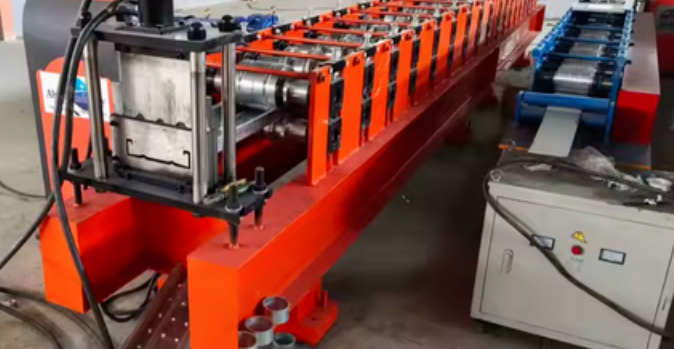

Machine Matcher supplies custom-built cable tray roll forming machines for manufacturers of electrical containment and cable management systems worldwide. These machines are designed to produce metal cable trays used to safely support and route electrical, data, and control cables in industrial, commercial, and infrastructure environments.

We match your exact cable tray profile, tray width, side height, slot or perforation pattern, material type, gauge, load rating, and production volume to the correct machine configuration — managing the full process from engineering review through delivery and long-term technical support.

All cable tray machines supplied by Machine Matcher are new, built to specification, and delivered globally through a secure, milestone-based purchasing process.

A cable tray roll forming machine is a specialized production line used to manufacture steel or aluminum cable trays that provide mechanical support and protection for electrical wiring systems.

Cable trays are critical in:

Electrical and data cable installations

Industrial plants and factories

Commercial buildings and data centers

Power generation facilities

Infrastructure and transport projects

Precision roll forming ensures consistent tray dimensions, accurate perforations, and reliable load-bearing performance.

Machine Matcher supplies all common cable tray machine configurations, including:

Produces ladder-style trays with side rails and cross members

High load capacity

Common in industrial and power applications

Produces trays with punched slots or holes

Improved ventilation and heat dissipation

Widely used in commercial buildings

Produces enclosed trays for sensitive cables

Used where dust or debris protection is required

Adjustable tray widths and side heights

Suitable for multiple product ranges

Reduced tooling investment

Designed for thick gauge and structural applications

Reinforced frames and high-capacity punching systems

Machine Matcher acts as your procurement and project partner, not just a machine supplier.

Share profile drawings, tray dimensions, slot or hole patterns, material type, gauge range, load requirements, and target production output.

We source the right manufacturer and provide a detailed quotation covering machine configuration, roll tooling, punching systems, automation level, lead time, and delivery.

Customer payments are handled by Machine Matcher and released to the manufacturer only after agreed production and inspection milestones are achieved.

Machines are tested on representative cable tray profiles, documented correctly for customs, and shipped to your facility.

Machine Matcher uses a milestone-based payment structure to reduce overseas purchasing risk.

30% deposit to begin production

70% balance after inspection and before shipment

50% at order confirmation

50% prior to shipment

For customs clearance, the commercial invoice is issued by the manufacturer and reflects machine value only.

Brokerage and coordination services are invoiced separately and are non-dutiable.

Cable tray roll forming machines are supplied worldwide, including:

United States & Canada

United Kingdom & Europe

Middle East

Africa

Asia-Pacific

South America

Buyers remain the Importer of Record, and Machine Matcher supports all shipping documentation and logistics coordination.

Machines can be configured to produce:

Ladder-type cable trays

Perforated cable trays

Solid-bottom cable trays

Custom tray widths and side heights

Region-specific electrical containment profiles

All machines are built to exact profile geometry, perforation accuracy, and load requirements.

Typical materials processed include:

Galvanized steel

Pre-galvanized steel

Stainless steel

Aluminum

Typical gauge ranges:

0.8 – 2.5 mm

Exact capability depends on tray width, side height, perforation density, and load rating.

Cable tray machines are used by:

Electrical containment manufacturers

Industrial and commercial contractors

Data center and telecom infrastructure suppliers

Power generation and utility companies

Infrastructure and transport project suppliers

Machines built to exact cable tray specifications

Secure, milestone-based payment handling

Vetted global manufacturers

Clean import and customs documentation

Global delivery coordination

Long-term technical and after-sales support

Send your cable tray drawings, dimensions, and load requirements, and Machine Matcher will match the right cable tray roll forming machine for your production needs.

👉 Request a Cable Tray Roll Forming Machine Quote

Steel Silo Roll Forming Machines for Sale Worldwide

Posted on Thursday, January 15, 2026

Heavy-Duty Roll Forming Machines for Agricultural & Industrial Storage Systems

Scaffold Equipment Roll Forming Machines for Sale Worldwide

Posted on Thursday, January 15, 2026

Heavy-Duty Roll Forming Machines for Scaffold & Access System Components

Highway Barrier Roll Forming Machines for Sale Worldwide

Posted on Thursday, January 15, 2026

Heavy-Duty Roll Forming Machines for Road Safety & Guardrail Profiles

Industrial & Infrastructure Roll Forming Machines for Sale Worldwide

Posted on Wednesday, January 14, 2026

Heavy-Duty Roll Forming Machines for Infrastructure, Public Works & Industrial Profiles

Copyright 2026 © Machine Matcher.