Posted on Monday, January 12, 2026

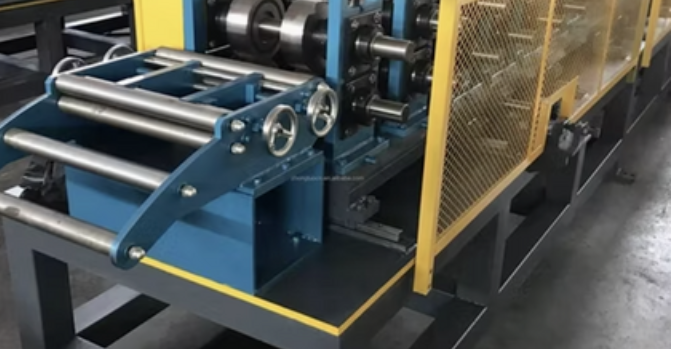

Machine Matcher supplies custom-built L profile roll forming machines for manufacturers and fabricators worldwide. These machines are designed to produce L-shaped metal profiles (angle sections) used across construction, industrial, and manufacturing applications.

We match your exact L-profile dimensions, material type, gauge range, and production speed to the right machine configuration — managing the entire process from specification and engineering review through delivery and long-term support.

All L profile roll forming machines supplied by Machine Matcher are new, built to specification, and delivered globally through a secure, milestone-based purchasing process.

An L profile roll forming machine is a roll forming line used to manufacture L-shaped metal sections, also referred to as L angles, angle profiles, or corner profiles.

These profiles are widely used for:

Structural support and bracing

Edge protection and framing

Cladding and panel termination

Shelving, racking, and industrial systems

L profiles are popular because they are simple, strong, and versatile, making them one of the most produced roll-formed sections worldwide.

Machine Matcher supplies all major L-profile machine configurations, including:

Fixed-size L profiles

High repeatability and consistency

Ideal for high-volume production

Variable leg lengths and angles

Manual or motorized adjustment

Suitable for manufacturers producing multiple sizes

Designed for thicker materials

Structural and industrial applications

Capable of producing L profiles alongside other simple sections

Quick changeover tooling options

Machine Matcher acts as your procurement and project partner, not just a machine supplier.

Submit Your L Profile Requirements

Share profile drawings, leg dimensions, material type, thickness range, and target production speed.

Machine Matching & Quotation

We source the right manufacturer and provide a detailed quotation covering machine configuration, tooling, automation level, lead time, and delivery.

Secure Payments & Production Control

Customer payments are handled by Machine Matcher and released to the manufacturer only after agreed production and inspection milestones are met.

Inspection, Shipping & Delivery

Machines are tested on representative L profiles, documented correctly for customs, and shipped to your facility.

Machine Matcher uses a milestone-based payment structure to reduce overseas purchasing risk.

30% deposit to begin production

70% balance after inspection and before shipment

50% at order confirmation

50% prior to shipment

For customs clearance, the commercial invoice is issued by the manufacturer and reflects machine value only. Brokerage and coordination services are invoiced separately and are non-dutiable.

L profile roll forming machines are supplied worldwide, including:

United States & Canada

United Kingdom & Europe

Middle East

Africa

Asia-Pacific

South America

Buyers remain the Importer of Record, and Machine Matcher supports shipping documentation and logistics coordination.

Machines can be configured to produce:

Equal-leg L profiles

Unequal-leg L profiles

Light-gauge angle profiles

Heavy-gauge structural angles

Custom corner and edge profiles

All machines are built to exact profile geometry and application requirements.

Typical materials processed include:

Galvanized steel

Pre-painted steel

Stainless steel

Aluminum

Typical gauge ranges:

0.6 – 3.0 mm (depending on design and duty level)

Exact capability depends on profile size, leg length, and required strength.

L profile roll forming machines are used across many industries, including:

Construction and building systems

Roofing and cladding manufacturing

Shelving and storage systems

Industrial fabrication

Infrastructure and support structures

Machines built to exact profile dimensions

Secure, milestone-based payment handling

Vetted global manufacturers

Clean import and customs documentation

Global delivery coordination

Long-term technical and after-sales support

Send your L-profile drawing or specifications, and Machine Matcher will match the right L profile roll forming machine for your production needs.

👉 Request an L Profile Roll Forming Machine Quote

Step Flashing Roll Forming Machines for Sale Worldwide

Posted on Monday, January 12, 2026

Precision Roll Forming Machines for Roofing Step Flashing Profiles

J Channel Roll Forming Machines for Sale Worldwide

Posted on Monday, January 12, 2026

Precision Roll Forming Machines for J Channel & J Trim Profiles

Corner Trim Roll Forming Machines for Sale Worldwide

Posted on Monday, January 12, 2026

Precision Roll Forming Machines for External & Internal Corner Trim Profiles

Drip Edge Roll Forming Machines for Sale Worldwide

Posted on Monday, January 12, 2026

Precision Roll Forming Machines for Roofing Drip Edge Profiles

Copyright 2026 © Machine Matcher.