To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

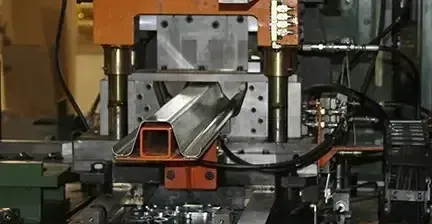

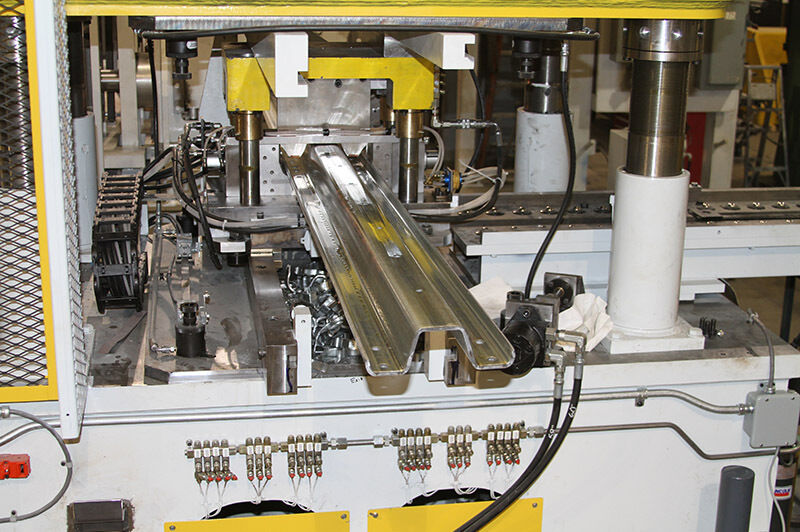

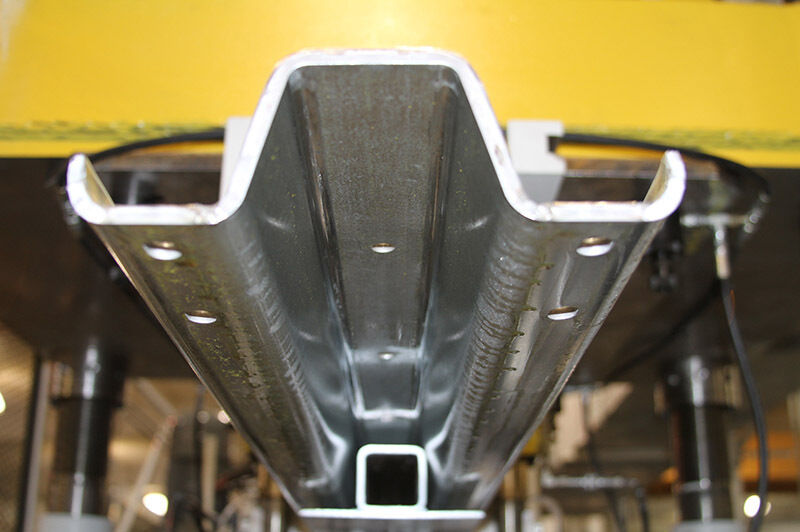

Grain bin stiffener roll forming machines are vital equipment used in the agricultural industry, specifically for manufacturing structural stiffeners for grain bins. These stiffeners are essential for providing strength and stability to large grain storage systems, ensuring durability under high loads and adverse weather conditions.

A Grain Bin Stiffener Roll Forming Machine is designed to produce stiffener profiles with precision and efficiency. The machine is fully automated and built to meet the high demands of grain bin manufacturers in the USA. It can handle various steel grades and gauges, ensuring compatibility with industry standards and customer requirements.

This roll forming machine includes advanced features like servo motors for precise feeding, hydraulic punching and cutting systems for customization, and a programmable logic controller (PLC) for easy operation. Its robust construction ensures longevity and reliable performance in high-volume production environments.

Q1: What materials can the Grain Bin Stiffener Roll Forming Machine process?

A1: The machine can process galvanized steel, high-strength steel, and other steel types with thicknesses ranging from 1.5mm to 4mm.

Q2: Can the machine produce custom stiffener profiles?

A2: Yes, the machine is equipped with adjustable tooling and a programmable PLC system to produce various custom stiffener designs.

Q3: What is the average production speed?

A3: The machine can produce stiffeners at speeds of up to 30 meters per minute, depending on the profile complexity and material thickness.

Q4: Are there any safety features included?

A4: Yes, the machine includes protective enclosures, emergency stop buttons, and overload protection to ensure operator safety.

Q5: Is training provided for operators?

A5: Many suppliers offer training for operators during installation to ensure smooth operation and maintenance.

Q6: How much space is required for installation?

A6: The machine requires approximately 12–15 meters of length and 3–4 meters of width, depending on the specific model and optional equipment.

Q7: What is the average lead time for delivery?

A7: Delivery times can range from 8 to 12 weeks, depending on customizations and the supplier's production schedule.

Q8: Are spare parts readily available in the USA?

A8: Yes, reputable suppliers ensure that spare parts are readily available, minimizing downtime during maintenance.

Q9: What industries typically use grain bin stiffener profiles?

A9: These profiles are primarily used in the agricultural industry for grain bins and silos but can also be utilized in industrial storage solutions requiring structural support.

Q10: How can I ensure long-term performance?

A10: Regular maintenance, such as lubrication, roller cleaning, and inspecting hydraulic systems, ensures optimal performance and longevity.

Copyright 2026 © Machine Matcher.