To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

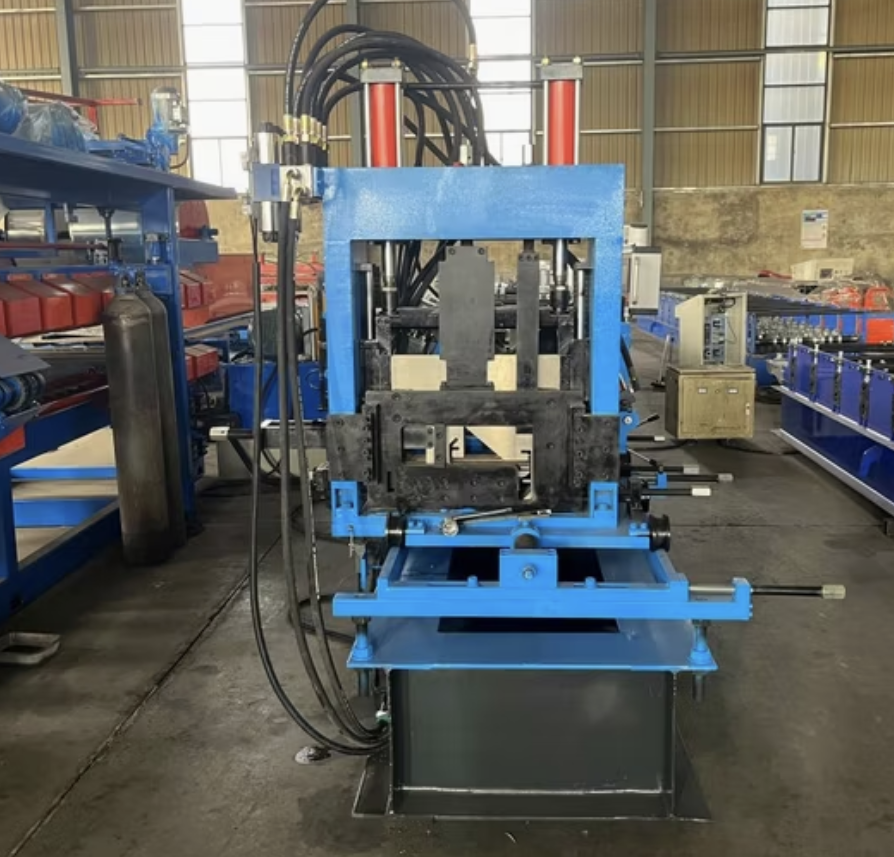

A C Purlin Roll Forming Machine is a specialized equipment designed for the efficient production of C-shaped purlins used in steel construction projects. These C purlins serve as structural supports for walls and roofs in steel-framed buildings, offering high strength and durability. The machine is engineered to convert galvanized or high-strength steel coil into a continuous, uniform C-profile with precise dimensions. Equipped with advanced technology, a C purlin roll forming machine is known for its automation capabilities, high production speed, and quality finish, making it ideal for high-volume production needs.

Q1: What materials can be used with the C purlin roll forming machine?

A1: The machine can process a variety of materials, typically galvanized steel, mild steel, and high-strength steel. Material thickness can range from 1.5 mm to 3.0 mm, depending on the machine’s capabilities.

Q2: How adjustable is the C purlin roll forming machine? Can it produce different sizes?

A2: Yes, the machine is highly adjustable. Most models allow for quick changes to produce different sizes and thicknesses of C purlins by adjusting the roller settings. This flexibility is ideal for producing customized profiles.

Q3: What are the main maintenance requirements?

A3: Regular maintenance includes lubrication of rollers, checking and tightening screws and bolts, ensuring hydraulic and electrical systems are functioning, and inspecting cutting blades. Scheduled maintenance improves machine longevity and performance.

Q4: How does the hydraulic cutting system benefit production?

A4: The hydraulic cutting system provides accurate cuts with minimal burrs, ensuring clean, professional finishes on each purlin. It also enables high-speed operation, which boosts productivity without sacrificing quality.

Q5: What safety features does a C purlin roll forming machine typically have?

A5: Most machines come with safety guards, emergency stop buttons, and overload protection. These features prevent accidents and ensure safe operation during high-speed production.

Q6: Can this machine integrate with other systems, like stackers or remote controls?

A6: Yes, many C purlin roll forming machines are designed for compatibility with additional systems such as stackers, automated uncoilers, and remote PLC control systems, which can further streamline production and handling.

Q7: What is the average lifespan of a C purlin roll forming machine?

A7: With regular maintenance, a C purlin roll forming machine can last anywhere from 10 to 15 years, depending on usage and operating conditions.

Q8: Is training required to operate the machine?

A8: Basic training is recommended for operators to understand machine settings, safety protocols, and maintenance requirements. Many suppliers offer on-site training as part of the purchase package.

Q9: What is the ideal production speed for high-quality output?

A9: Although the machine can reach speeds up to 30 meters per minute, the ideal speed varies depending on the material thickness. Lower speeds may be better for thicker materials to maintain precision and reduce wear on the machine.

Copyright 2026 © Machine Matcher.