To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

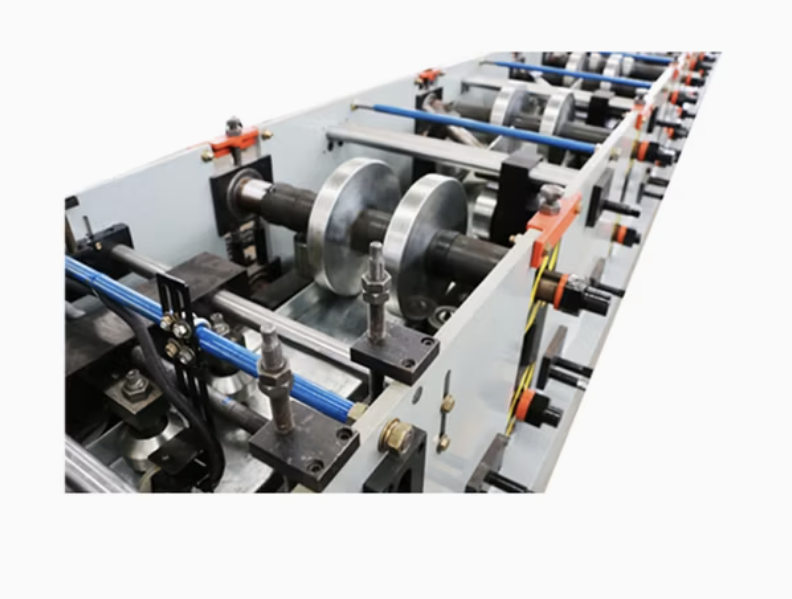

C Z Purlin Roll Forming Machines are specialized manufacturing equipment designed for producing structural C and Z purlins used in building construction, particularly for roofing and wall support. These machines are highly versatile and can manufacture purlins of various sizes and thicknesses with minimal manual adjustments.

The C Z Purlin Roll Forming Machine is a cutting-edge piece of machinery tailored to meet the needs of the construction industry. These machines streamline the production process, offering fast, precise, and customizable solutions for fabricating steel purlins.

The machine operates on a hydraulic and PLC-based system, allowing for seamless switching between C and Z profiles without the need for replacing rollers or other mechanical parts. With advanced automation, this machine provides consistent quality, high production speed, and minimal material wastage.

| Category | Details |

|---|---|

| Material | Galvanized steel, mild steel, and stainless steel |

| Material Thickness | 1.5 mm – 3.0 mm (customizable up to 5 mm) |

| Profile Sizes | Width: 80–300 mm; Height: 40–80 mm |

| Machine Speed | 15–25 meters per minute |

| Roller Material | High-grade steel with hard chrome plating |

| Cutting System | Hydraulic cutting with post-cut or pre-cut options |

| Power Supply | 220V/380V/415V, 50/60Hz (customizable) |

| Motor Power | 7.5–15 kW (main motor) + 5.5 kW (hydraulic) |

| Control System | PLC with touch screen (brands like Siemens or Mitsubishi) |

| Dimensions | 10m x 1.5m x 1.2m (approx.) |

| Weight | 10–15 tons |

| Optional Extras | Pre-punching, stackers, embossing, remote control |

Q1: What materials can the machine process?

A: The machine can process galvanized steel, mild steel, stainless steel, and other alloys with thicknesses ranging from 1.5 mm to 5 mm, depending on customization.

Q2: Is the C Z Purlin Roll Forming Machine easy to operate?

A: Yes, the machine is equipped with a PLC control system and a user-friendly interface. Minimal training is required to operate the machine efficiently.

Q3: How does the machine switch between C and Z profiles?

A: The machine features an automatic or semi-automatic mechanism that adjusts rollers and guides for seamless switching without changing tools.

Q4: What power supply is required for the machine?

A: Standard configurations use 380V, 50Hz, three-phase power. However, the machine can be customized for 220V or 415V depending on the client’s location.

Q5: What optional extras are available?

A: Optional extras include pre-punching units, stackers, coil feeders, embossing systems, and remote control functionality for enhanced production capabilities.

Q6: Can the machine produce custom profiles?

A: Yes, the machine can be configured to produce custom sizes and profiles, depending on the specifications provided during purchase.

Q7: What is the typical maintenance required for this machine?

A: Regular maintenance includes lubrication of moving parts, inspection of the hydraulic system, roller cleaning, and ensuring the PLC system is functioning correctly.

Q8: What is the delivery time for the machine in the USA?

A: Delivery typically takes 8–12 weeks from the date of order confirmation, depending on customizations and shipping arrangements.

The C Z Purlin Roll Forming Machine is an essential tool for modern construction projects in the USA. Its high efficiency, durability, and ability to produce versatile profiles make it a valuable investment for contractors, manufacturers, and industrial builders. With its advanced automation and precision engineering, this machine ensures consistent quality and high productivity, helping businesses meet the demands of the growing construction market.

Copyright 2026 © Machine Matcher.