To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

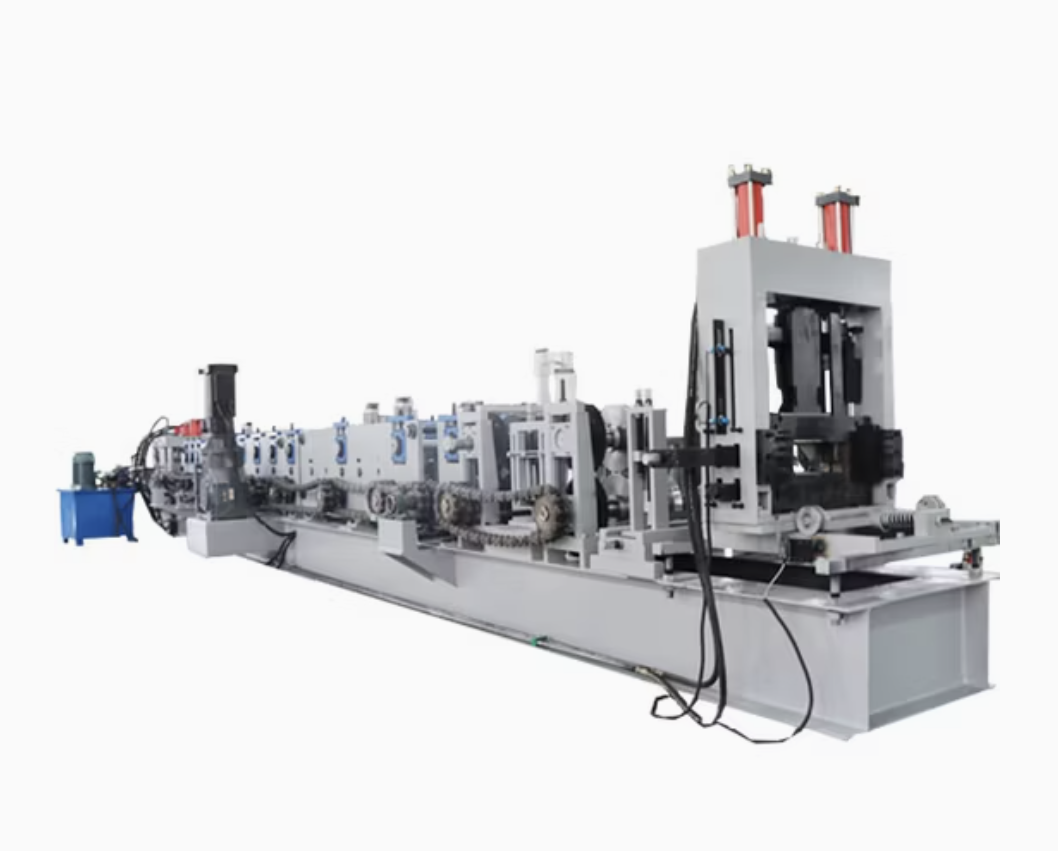

A CZ roll forming machine is a versatile piece of equipment used in the construction industry for producing C and Z-shaped steel profiles, which are widely used in structural framing, roofing systems, and metal building construction. This machine can switch between producing C and Z profiles with minimal adjustments, enhancing efficiency and reducing downtime. CZ roll forming machines are popular in sectors requiring precise, high-quality profiles with excellent structural integrity.

| Specification | Details |

|---|---|

| Profile Type | C and Z profiles |

| Material Thickness | 1.5mm – 3.5mm (can vary based on model) |

| Material Width | 80mm – 300mm (customizable) |

| Roller Material | High-grade steel, often with chrome coating for durability |

| Motor Power | Typically ranges from 7.5 kW to 22 kW depending on model |

| Cutting System | Hydraulic or servo cutting system |

| Forming Speed | Up to 30m/min (can vary with thickness and profile dimensions) |

| PLC Control System | Integrated PLC with user-friendly interface |

| Changeover Mechanism | Automatic C to Z profile changeover feature |

| Main Frame Construction | Heavy-duty steel for stability and reduced vibration |

| Hydraulic Power Pack | High-capacity power pack for efficient cutting and punching |

| Machine Dimensions | Varies by model, typically compact to save space |

| Safety Features | Safety guards, emergency stop buttons, and overload protection |

| Optional Extras | Remote PLC system, stacker, coil handling systems, and automatic feeders |

Q1: What materials are suitable for CZ roll forming machines?

A: CZ roll forming machines can handle a variety of materials, including galvanized steel, stainless steel, and mild steel. The specific material compatibility depends on the machine model and material thickness.

Q2: How does the machine switch between C and Z profiles?

A: Most modern CZ roll forming machines feature an automated changeover system that allows operators to switch from C to Z profiles by adjusting certain settings in the control panel without manual tooling adjustments.

Q3: What industries benefit the most from CZ roll forming machines?

A: CZ roll forming machines are primarily used in the construction industry, especially for structural framing, purlins, roofing, and wall support in industrial and commercial buildings.

Q4: How long does it take to produce a profile?

A: Production speed varies by machine model and profile dimensions but typically ranges between 15-30 meters per minute. Factors such as material thickness and complexity of the profile shape may impact speed.

Q5: Can I adjust the flange height and width for customized profiles?

A: Yes, most CZ roll forming machines allow for customization of flange height and width, enabling production of profiles that meet specific project requirements.

Q6: What safety features are included in CZ roll forming machines?

A: CZ roll forming machines are equipped with safety guards, emergency stop buttons, overload protection, and other features to ensure the safety of operators during machine operation.

Q7: What is the typical maintenance required for CZ roll forming machines?

A: Regular maintenance includes cleaning the machine, lubricating moving parts, checking and tightening bolts, and inspecting hydraulic and electrical systems to ensure optimal performance.

Q8: Are there options for remote monitoring or PLC control?

A: Yes, many models offer remote PLC control options, allowing operators to monitor and adjust settings remotely, which is particularly useful for large-scale production facilities.

Q9: What optional extras are available for CZ roll forming machines?

A: Optional extras include stackers, coil car tippers, automatic feeders, remote PLC systems, and uncoilers and recoilers, which enhance the machine's efficiency and adaptability for high-volume production.

Q10: How does the hydraulic cutting system benefit the machine?

A: The hydraulic cutting system provides clean, precise cuts without causing deformation to the profile, ensuring high-quality end products.

Copyright 2026 © Machine Matcher.