To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

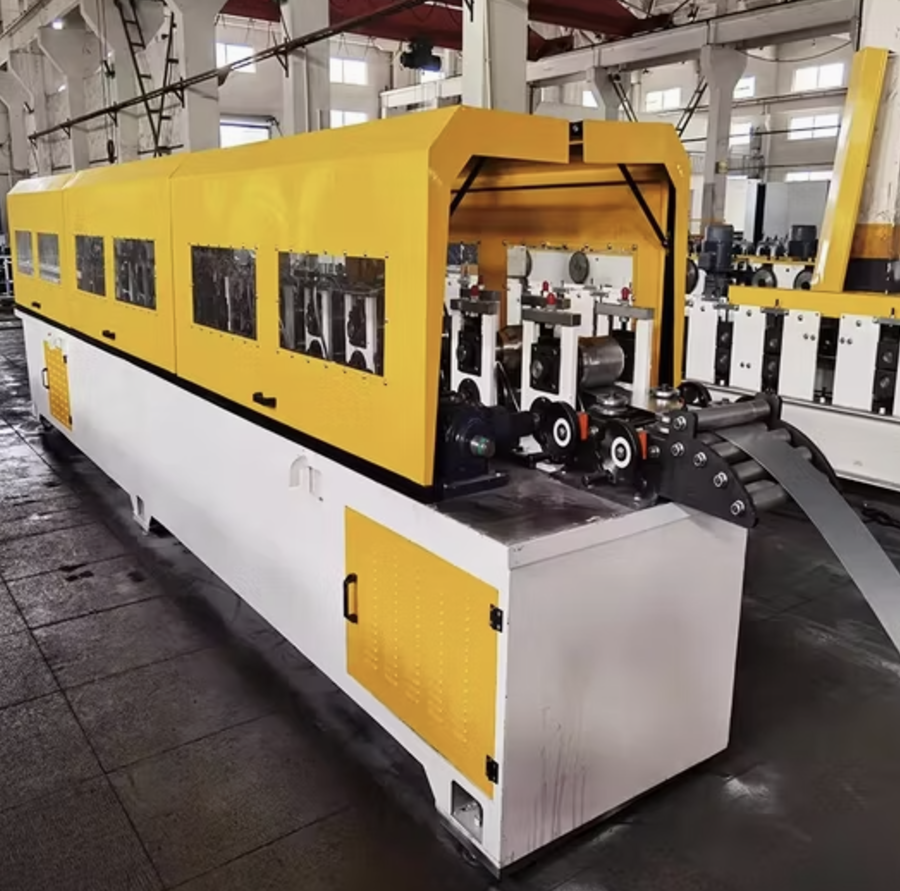

Garage door roll forming machines are specialized equipment designed to produce high-quality, precisely shaped metal panels and sections used in the construction of garage doors. These machines are essential for manufacturers looking to achieve consistency, efficiency, and durability in their production processes. In Canada, where weather conditions demand sturdy and insulated garage doors, the demand for roll forming machines that produce such profiles is consistently high.

A garage door roll forming machine fabricates metal panels and tracks used in garage doors. The equipment processes pre-painted steel, galvanized steel, or aluminum coils, forming them into the desired shapes. The machine integrates advanced technology, ensuring precise cutting, punching, and profiling.

Features like automatic coil feeding, servo-driven motors, and hydraulic cutting ensure smooth operation and high production efficiency. Additionally, optional features such as embossing rollers and insulation material applicators can be added for versatility.

Here are the general specifications for a standard garage door roll forming machine:

Answer: These machines provide precision, efficiency, and consistency, making them ideal for manufacturing high-quality garage doors that can withstand Canada’s harsh weather conditions.

Answer: Yes, many garage door roll forming machines come with optional insulation applicators for adding thermal or acoustic insulation during the manufacturing process.

Answer: Common material thickness ranges from 0.4 mm to 1.2 mm, depending on the application (residential or commercial).

Answer: The production speed is typically between 12–20 meters per minute, though it can vary based on the machine configuration.

Answer: While no specific certifications are mandatory, compliance with CSA (Canadian Standards Association) and electrical safety standards is often required.

Answer: Regular maintenance, including lubrication, cleaning, and inspection of hydraulic and electrical systems, will ensure the machine operates efficiently for years.

Garage door roll forming machines are essential for businesses in Canada aiming to manufacture durable and high-quality garage doors. With their advanced specifications and capabilities, these machines cater to the growing demand for energy-efficient and robust garage door panels. By understanding the specifications, setup, and maintenance requirements, manufacturers can maximize productivity and ensure long-term success in their operations.

Copyright 2026 © Machine Matcher.