To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

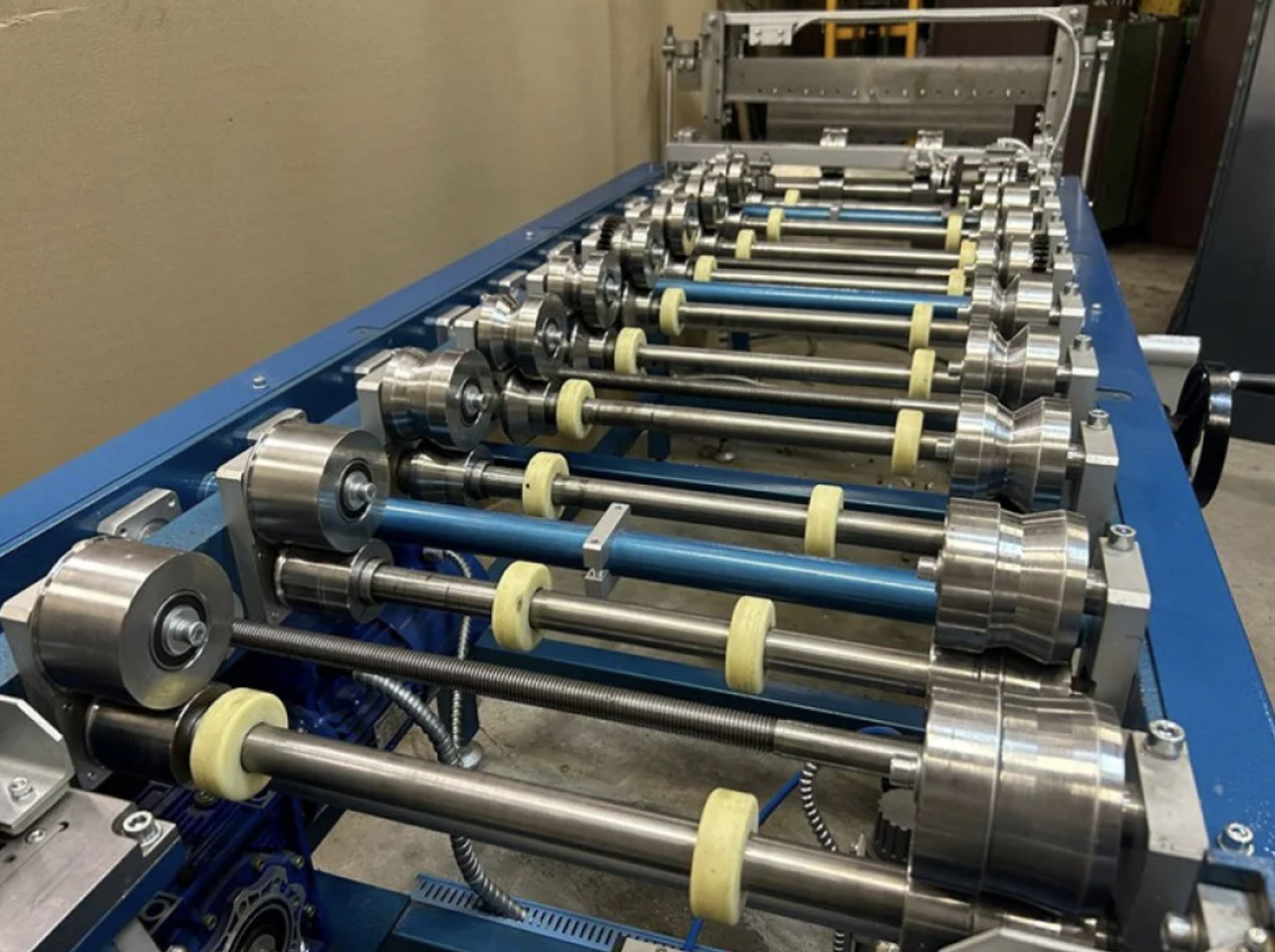

The Snap Lock Roofing Roll Forming Machine is designed to manufacture high-quality snap lock roofing panels, which are ideal for residential, commercial, and industrial applications. Snap lock panels are known for their interlocking mechanism, which simplifies installation and provides superior weather resistance.

In New Zealand, the Snap Lock roofing profile is particularly suitable for regions with varying climates, including coastal areas where corrosion resistance is critical. The machine is engineered to deliver precision, efficiency, and long-lasting durability, catering to the needs of roofing professionals and builders in the country.

1. Roller Materials:

2. Hydraulic Cutting System:

3. Frame Size:

4. Motor and Drive System:

5. PLC Control System:

6. Machine Speed:

7. Safety Features:

8. Panel Specifications:

9. Optional Add-Ons:

New Zealand’s varied climate, ranging from temperate inland regions to harsh coastal conditions, requires roofing solutions that are both durable and weather-resistant. Snap lock roofing meets these demands with its unique features:

Q1: Why is Snap Lock roofing suitable for New Zealand?

A1: Snap Lock roofing is ideal for New Zealand due to its corrosion resistance, ease of installation, and excellent weatherproofing, which suits the country's diverse climates, especially coastal areas.

Q2: What materials can this machine process?

A2: The machine can process galvanized steel, pre-painted steel, zinc-aluminum, aluminum, and copper, all of which are commonly used in New Zealand roofing.

Q3: How does the machine ensure precision?

A3: Precision is achieved through high-quality rollers, a hydraulic cutting system, and advanced PLC control, ensuring consistent panel dimensions and clean cuts.

Q4: What is the typical production speed?

A4: The standard production speed is 15–20 meters per minute, with high-speed options available up to 30 meters per minute.

Q5: Is the machine energy-efficient?

A5: Yes, the machine uses energy-efficient motors and can be customized to meet New Zealand’s power supply standards (230–400V, 50Hz).

Q6: What are the safety features of this machine?

A6: The machine includes safety enclosures, emergency stop buttons, and alarms to ensure operator safety during use.

The Snap Lock Roofing Roll Forming Machine is a valuable investment for New Zealand’s roofing industry, offering durability, efficiency, and suitability for the country’s varied climates. Whether used in coastal or inland regions, this machine delivers high-quality panels that meet local building standards and aesthetic preferences. For builders and contractors, it provides an excellent return on investment by simplifying production and installation processes.

Copyright 2025 © Machine Matcher.