To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

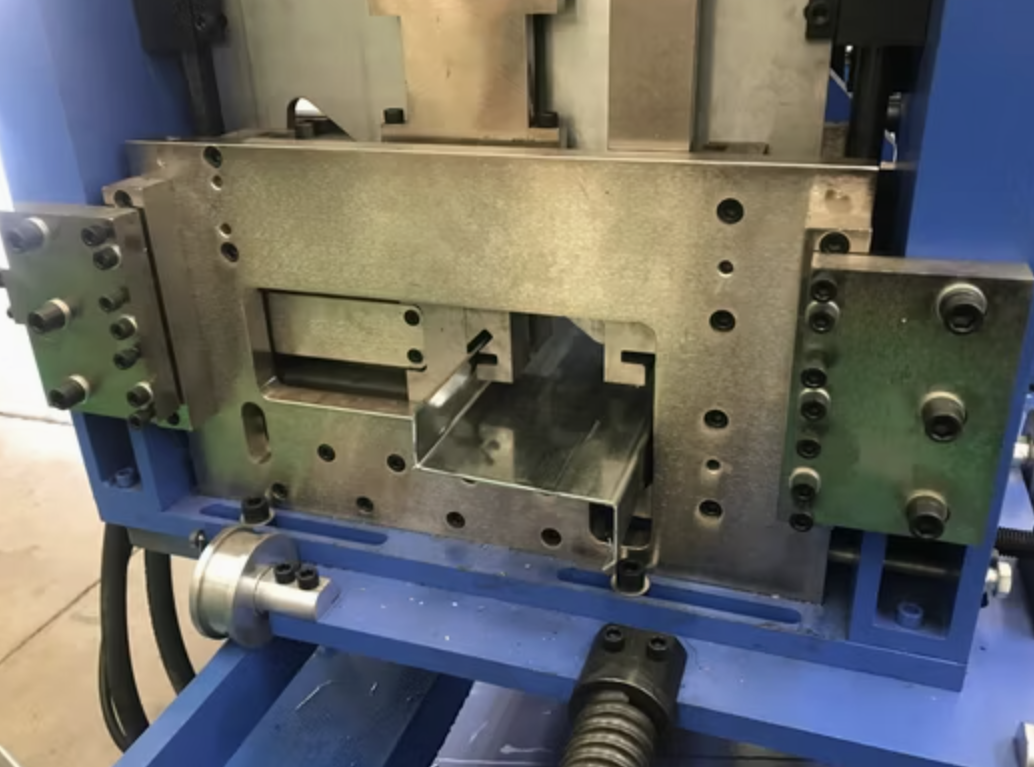

A steel stud roll forming machine is a specialized industrial machine designed to produce steel studs and tracks, which are commonly used in the construction industry for creating wall partitions, ceilings, and other structural frameworks in both commercial and residential buildings. The machine uses a series of rollers to shape a continuous strip of metal into precise, high-quality steel studs and tracks. Steel studs made by these machines are widely used due to their strength, durability, and ease of installation, making them a preferred alternative to traditional wooden framing.

Copyright 2026 © Machine Matcher.